Motor brushes are a crucial component in many types of electrical machines, including motors and generators. These small but mighty devices play a significant role in ensuring the smooth operation and optimal performance of the motor. In this article, we will explore the importance of motor brushes and their function in electrical machines.

What are Motor Brushes?

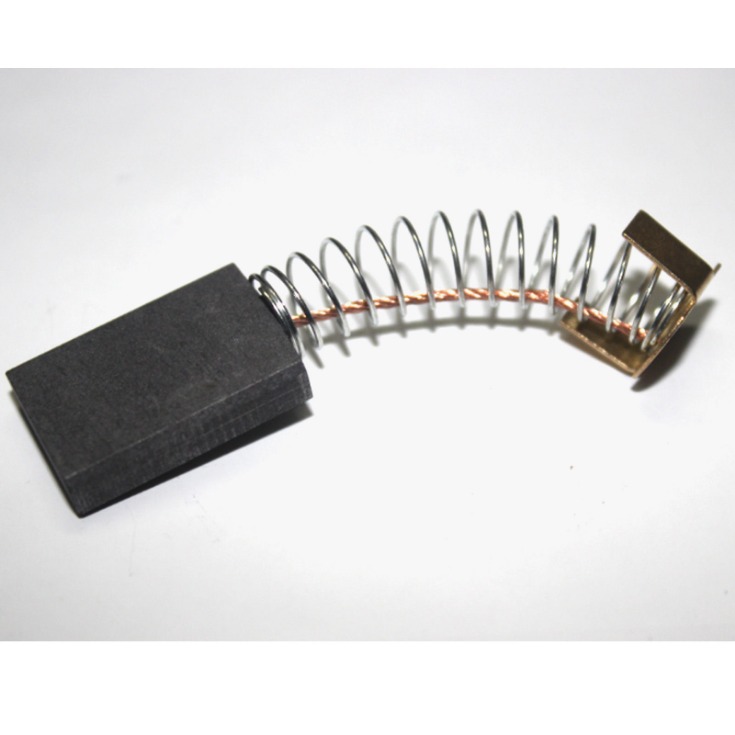

Motor brushes are conductive materials, typically made of carbon, that deliver electrical current between stationary wires and moving parts in an electrical machine. They are designed to make smooth and consistent contact with the rotating part of the motor, enabling the transfer of electrical energy that powers the machine.

Function of Motor Brushes

The primary function of motor brushes is to transfer electrical current from the power source to the rotating part of the motor. As the motor rotates, the brushes maintain contact with the commutator or slip rings, ensuring a continuous flow of electricity to the moving components. This process enables the motor to operate efficiently and generate the desired mechanical output.

Motor brushes also play a crucial role in regulating the speed and torque of the motor. By controlling the flow of electricity to the motor, the brushes help maintain the desired speed and power output of the machine. Additionally, motor brushes aid in reducing friction and wear on the moving parts of the motor, prolonging its lifespan and improving overall efficiency.

Importance of Regular Maintenance

It is essential to regularly inspect and replace motor brushes to ensure the optimal performance of electrical machines. Over time, motor brushes can wear down due to friction, heat, and other factors, leading to decreased contact with the commutator or slip rings. This can result in poor electrical conductivity, increased resistance, and reduced efficiency of the motor.

Read more about Motor brushes here.

Regular maintenance and replacement of motor brushes can help prevent issues such as overheating, sparking, and motor failure, ensuring the reliable operation of electrical machines.

In conclusion, motor brushes are a critical component in electrical machines, enabling the transfer of electrical current and regulating the speed and torque of the motor. Regular maintenance and replacement of motor brushes are essential to ensure the optimal performance and longevity of electrical machines. By understanding the importance of motor brushes and their function in electrical machines, we can appreciate the vital role they play in powering a wide range of devices and equipment.